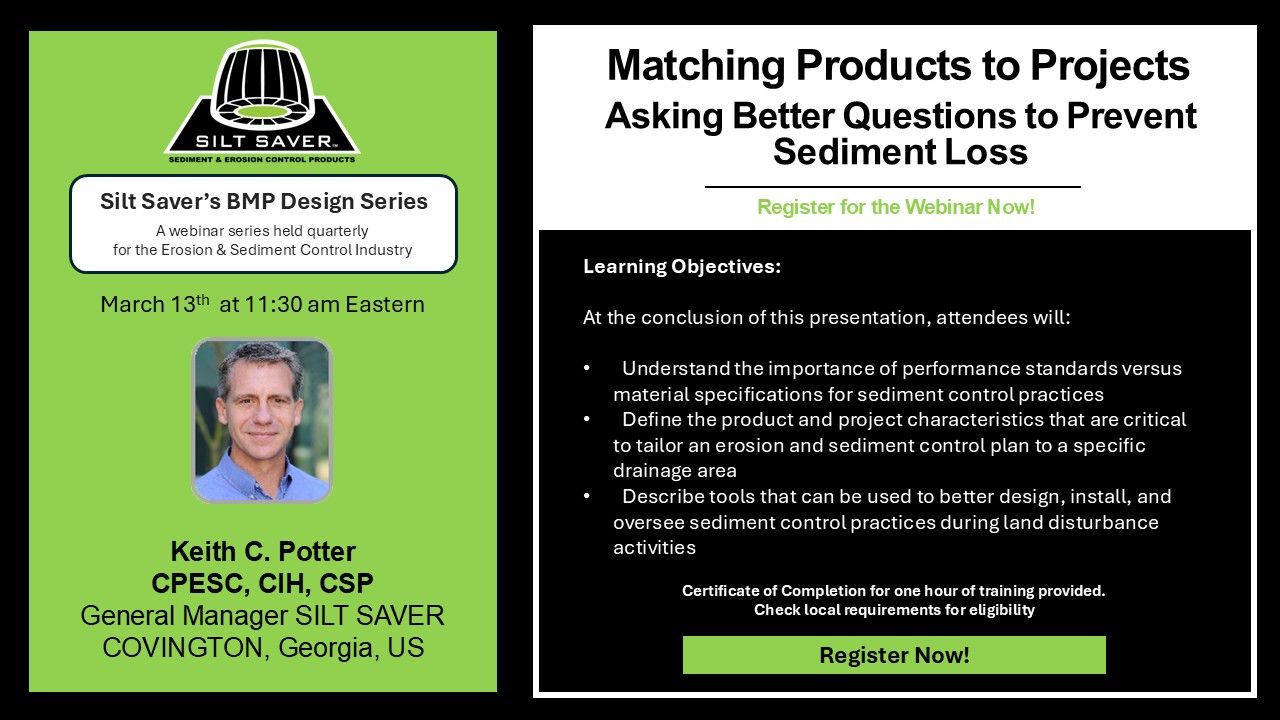

Matching Products to Projects – Asking Better Questions to Prevent Sediment Loss

Because there are no established performance standards for sediment control devices, products for a specific practice (e.g. perimeter sediment barriers, inlet protection, slope/channel interruption) are typically approved based on material specifications that do not correlate to actual field performance. Therefore once the project begins, the least expensive product is chosen despite there are better performing products available for that specific project. This presentation will explore tools to model performance of sediment control products based on product specific properties and project specific conditions. These tools ask better questions to predict performance and ensure compliance as opposed to considering all products and all projects the same. The output of the models will be validated based on case studies of projects.

Full Abstract: Most states or municipalities have specific symbols for Best Management Practices (BPMs) that must be shown on erosion and sediment control plans to submit a Notice of Intent for coverage under a Construction General Permit (CGP). Typically, there is a description of the BMP and possibly a material specification or even an approved products list for the materials required by that practice. It has long been recognized that material specifications and the test methods used to measure these index properties, while providing information about the fabric, do not model field performance1. Because there is no correlation between these index properties and field performance, it is not surprising that failures resulting in uncontrolled discharges of sediment during construction are pervasive.

A better question to ask is can one utilize product specific data to model sediment barrier performance based on site specific project conditions? Utilizing design tools such as the

International Erosion Control Association (IECA) Silt Fence Design Guide and SEDCADTM 4, one can model the runoff and sediment removal efficiency of silt fence sediment barriers. This study will model the benefits of 2-stage variable flow geotextile fabrics to impound recommended depths of 12” to 18” while providing controlled release of the runoff exceeding that recommended depth. In addition, models will be developed to assess the impact of multiple sediment retention structures in series on runoff volume and sediment removal efficiency. Finally, similar modeling will be conducted and validated in a field case study.

1 Barrett et al., “An evaluation of geotextiles for temporary sediment control,” Water Environment Research, Volume 70, Number 3, p 283-290.

Learning Objectives:

At the conclusion of this presentation, attendees will:

Understand the importance of performance standards versus material specifications for sediment control practices

Define the product and project characteristics that are critical to tailor an erosion and sediment control plan to a specific drainage area

Describe tools that can be used to better design, install, and oversee sediment control practices during land disturbance activities